Here are some tips to help you do that:

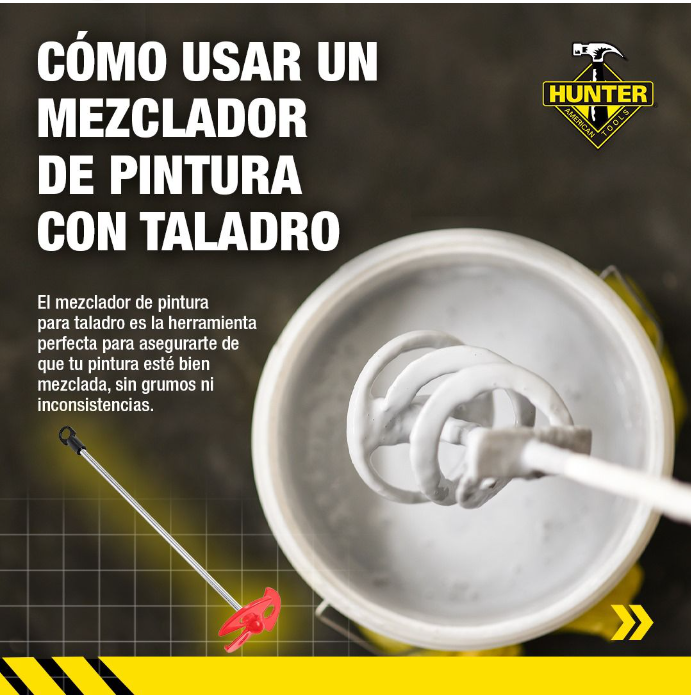

- Use the right tool for the job – Using a power tool for a job it is not designed for can damage it and cause it to wear out faster. Always make sure you are using the right tool for the job.

- Keep Them Clean: Clean your power tools regularly, especially after using them. Dust, debris, and moisture can damage the tool’s internal parts, reducing performance and reducing tool life.

- Lubricate moving parts: Regular lubrication of moving parts such as gears, bearings, and motor can help reduce friction, prevent wear, and extend the life of your power tools.

- Store them properly: When not in use, store your power tools in a dry, safe place. Keep away from moisture and extreme temperatures, which can damage tool components

- Perform regular maintenance: Follow the manufacturer’s recommended maintenance schedule for your power tools. Regular maintenance, such as replacing worn parts and cleaning filters, can help extend the life of the tool.